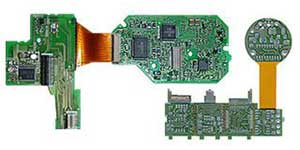

Rigid Flexible Circuits consist of rigid and flexible substrates that are bonded together to create a single structure. Rigid flex can be created as either a multilayer design if you require enhanced circuit density or we can design a double sided for smaller applications. Contact our engineers to discuss your options.