Flex PCB Manufacturer

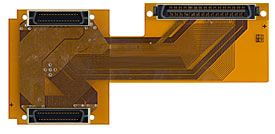

Northpoint Technologies, Inc. is a flex PCB manufacturer in the USA with manufacturing capabilities in Mexico and China. PCB is like a layer cake, there are alternating layers of different materials which are laminated together with heat and adhesive. Double layer PCB manufacturing, also known as Double-Sided Printed Circuit Board, is a printed circuit board that has two layers conductive pattern. Double Sided PCBs circuits allow for closer (and more) routing traces by alternating between a top and bottom layer using vias. Today, double sided printed circuit board technology is the most popular type of PCB in the industry.

Understanding key components about flex PCB manufacturing are attachment pins which are pins can be added as conductor extensions, solder pins or other options. Placing adhesive in key locations allows improvement in circuit placement and mounting. With increasing concerns with electromagnetic interference and emissions from circuits, shielding specifications can reduce these risks. On single-sided circuits, conductor traces and spaces are available in .002”. On double-sided and multi-layer circuits, conductor traces and spaces are available in .003”-.004”. Connectors are flex circuits with assembled connectors allow for faster assemblies. Stiffeners are used to rigidize circuits in the component areas. Stiffener frames to assist wave soldering, clips apart and folds into position. Flex interconnects are used to connect rigid boards together allowing folding and positioning to solve high-density packaging problems.

Click on a product below for more information.