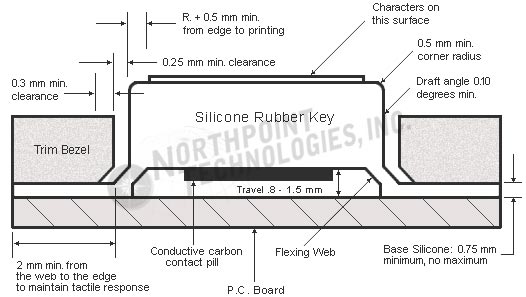

DESIGN GUIDE: SILICONE RUBBER KEYPADS & CONDUCTIVE RUBBER KEYPADS

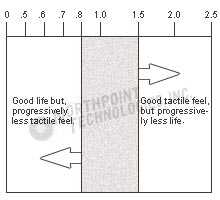

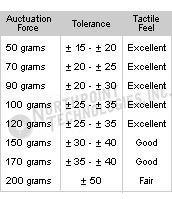

Button Travel

Note: For good tactile feel a travel of1.2 mm and a force of 135 grams is recommended.

Typical Effects

Above effects are estimated according to typical key structures.

Rubber Keypad – General Specification

| Travel | 0.8 – 1.5 mm |

| Force | 60 – 300 grams |

| Tactile Response | Yes |

| Life Cycles | 1,000,000 |

| Operating Temperature | -40° to + 150°C |

| Storage Temperature | -50° to + 170°C |

| Dielectric Strength | >1 min @ 500 VRMS |

| ESD Breakdown | 20KV/MM |

| Contact Bounce | <5MS |

| Contact Resistance | <200 Ohms |

Physical Properties of Silicone Rubber

| Typical Physical Property | Carbon Conductor | Silicone Insulator |

| Specific Gravity@ 72°C | 1.18 | 1.17 |

| Durometer Hardness (Shore A) | 65 ± 5 | 30-80 ± 5 |

| Tensile Strength (KG/CM) | >50 | >70 |

| Elongation (%) | >100 | >250 |

| Tear Strength (KG/CM | >9 | >12 |

| Linear Shrinkage (%) | 3 – 5 | 3 – 4.5 |

| Volume Resistivity (Ohm/CM) | <5 | 1×1015 |

Dimensional Tolerances

| Dimension | Tolerances | ||

| Inches | MM | Inches | MM |

| 0 – .987 | 0 – 25 | .005 | .13 |

| .998 – 1.460 | 25.1 – 37 | .008 | .20 |

| 1.461 – 1.971 | 37.1 – 50 | .010 | .25 |

| 1.972 – 2.444 | 50. – 1-62 | .012 | .31 |

| 2.445 – 2.956 | 62.1 – 75 | .015 | .38 |

| 2.957 – 3.428 | 75.1 – 87 | .017 | 44 |

| 3.429 – 3.940 | 87.1 – 100 | .020 | .50 |

| 3.491 – 5.908 | 100.1 – 150 | .024 | .62 |

| 5.909 – OVER | 150.1 – OVER | 0.5% | 0.5% |